证券代码

837263

为了更全面的分析检测半导体器件内部的结构特性、和质量缺陷。使用超声扫描成像检测方法对器件内部检测分析:

原理:这种无损检测手段利用超声波良好的方向性、穿透性、定位性、灵敏度高特性以及在不同介质中结合面会形成反射波与折射波等特性。人们通过收集这些声波,利用计算机技术将收集来的脉冲信号做相应的图像化处理,用于检测材料内部中各种不同类型的缺陷如:裂纹,缝隙、空洞、气泡、夹渣、分层等……可以使检测结果更精准、检测精度更高、分辨力更强等优势。

在半导体产品中,裂纹、分层、气孔、夹渣、等缺陷在正常使用过程中扩展或者局部腐蚀。可能会进一步引发内部断线造成产品性能失效。超声扫描检测成像技术用于对试件进行缺陷检测,几何特征定位、内部组织结构、以及力学性能变化特征,产品质量评估、改进生产工艺、产品可靠性等方面都起着重要的作用。

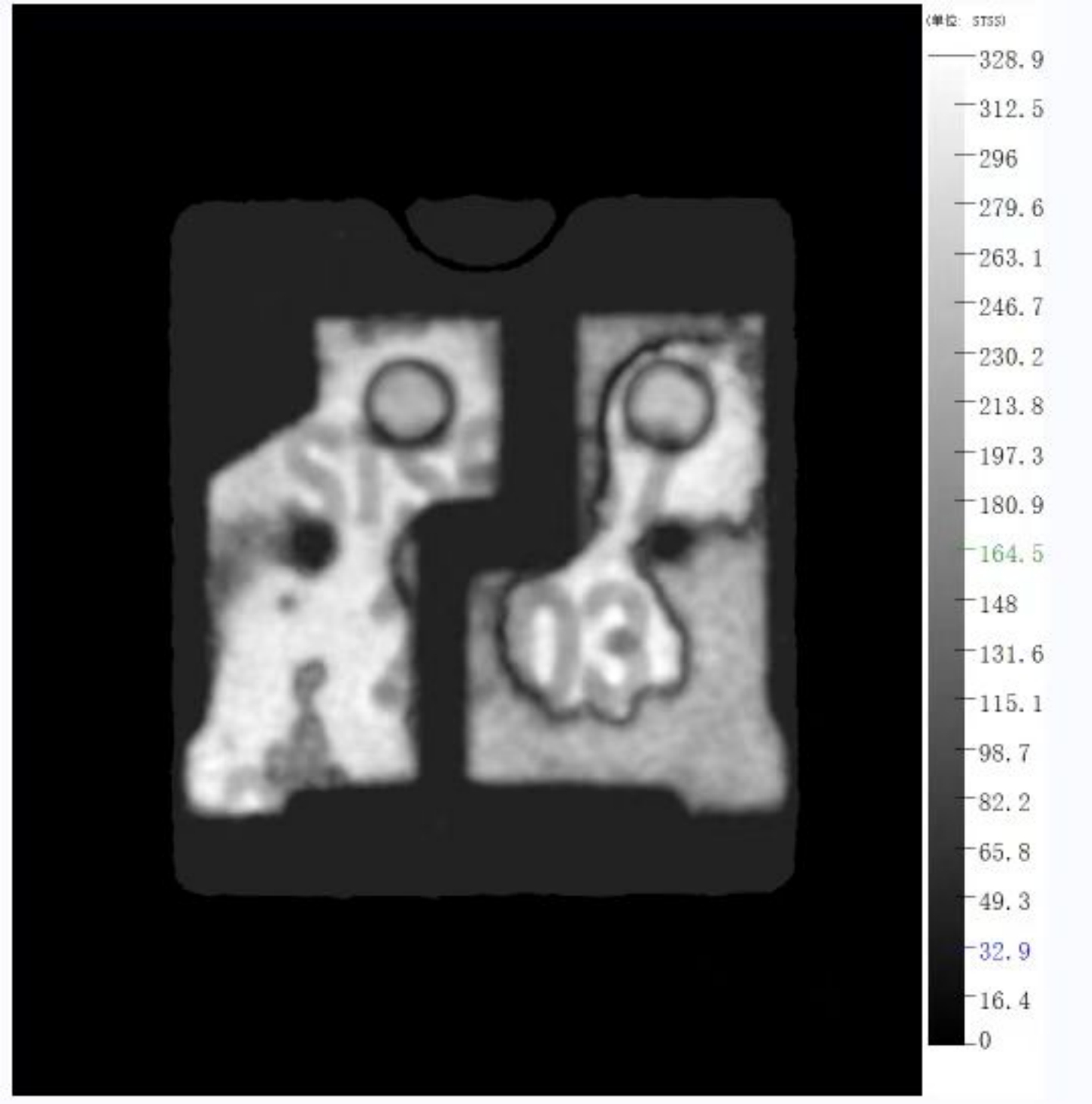

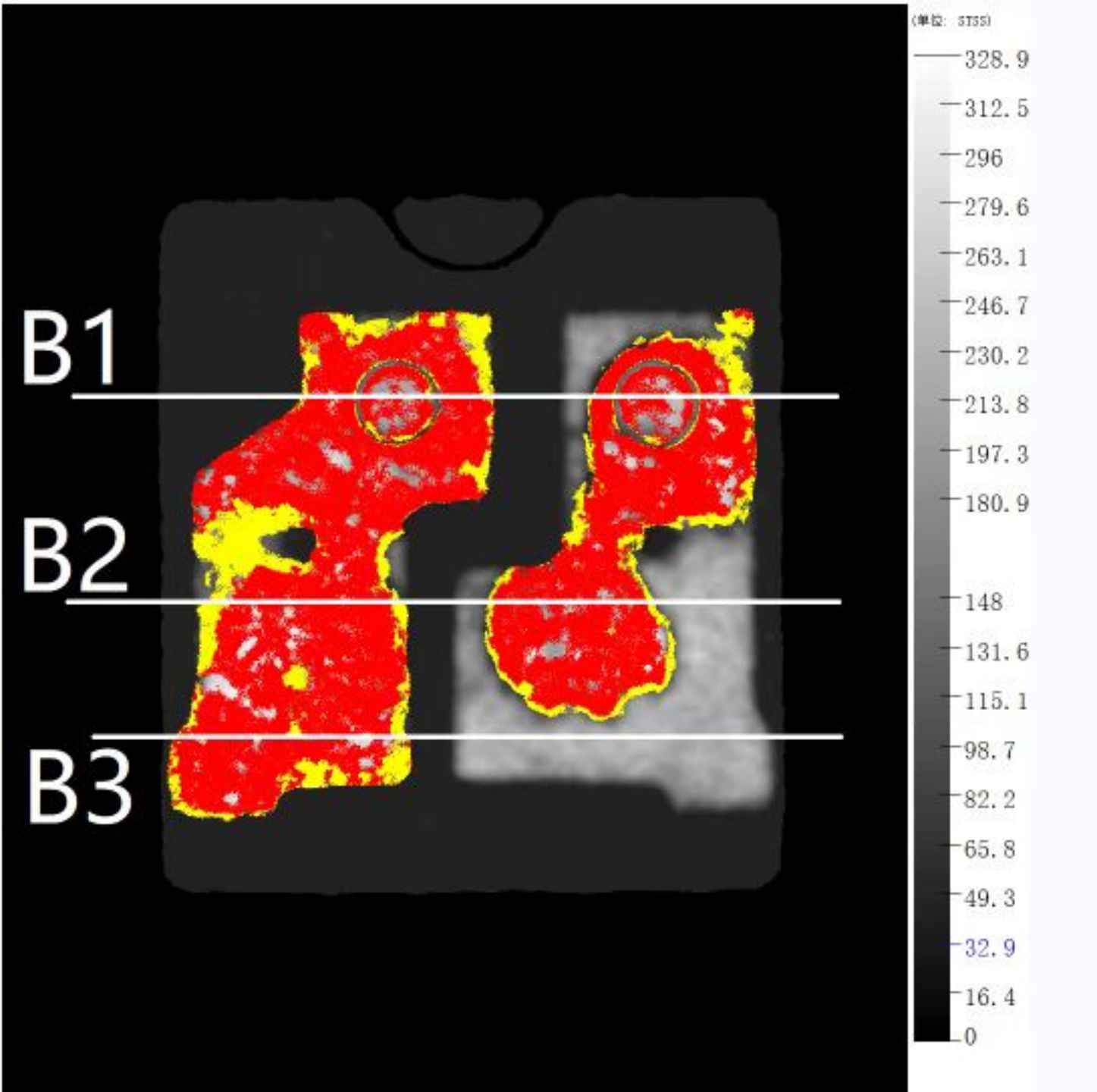

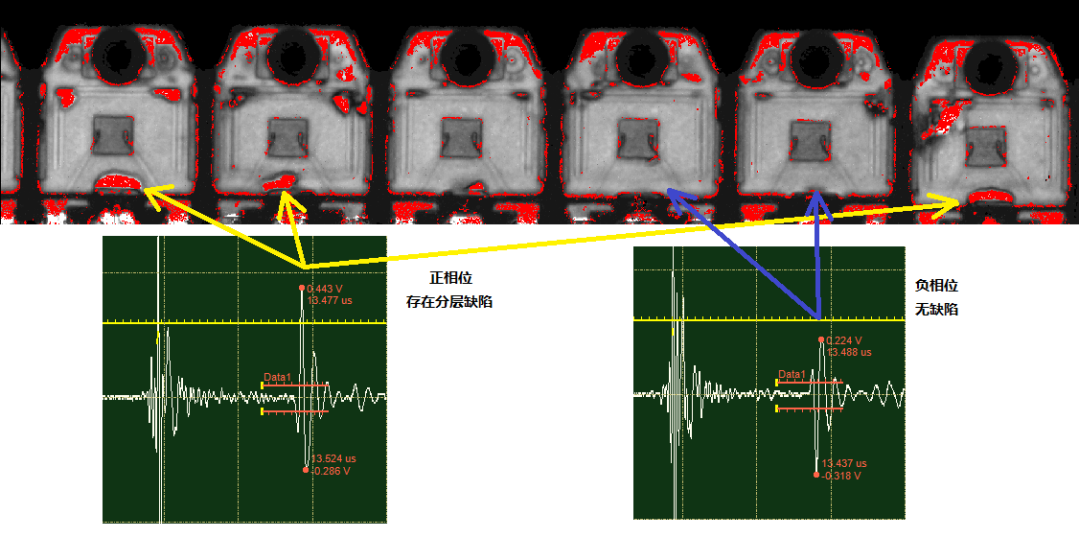

半导体内部分层缺陷超声扫描检测一般可利用超声扫描的反射法以及透射法。对材料内部分层缺陷进行判断。

1.反射法:

反射法:是利用超声换能器发射超声波和接收超声波信号,将超声脉冲通过耦合介质发射到材料内部。

在材料内部不同介质交界面上(分层缺陷界面处)会形成不同的脉冲回波。通过观察来自材料内部分层界面的反射波的情况利用计算机进行图像化处理,进而可以达到对半导体分层缺陷的判断分析。反射方法适用范围广泛,扫描模式丰富。灵敏度高,是超声扫描成像检测设备的主流检测方法。

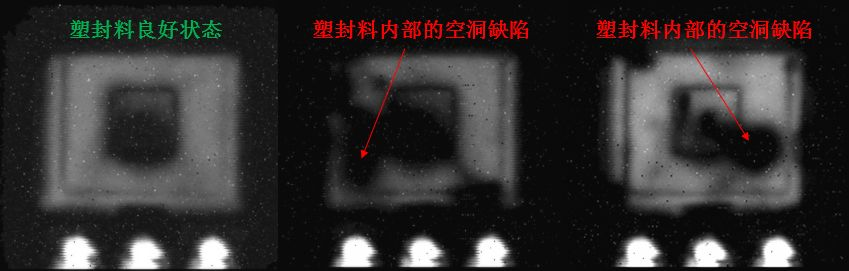

2.透射法:

透射法是将发射、接收超声换能器分别置于检测期间的上下两端。使两个换能器的声轴线处于同一直线上。聚焦后进行检测。

根据超声穿透材料后的波的强弱来进行对材料内部结构的判断。透射法几乎不存在盲区,且超声波是单向传播、衰减小。对于材料整体内部结构、缺陷位置分布分析上面有较为客观的判断。

3.水浸超声扫描显微镜:

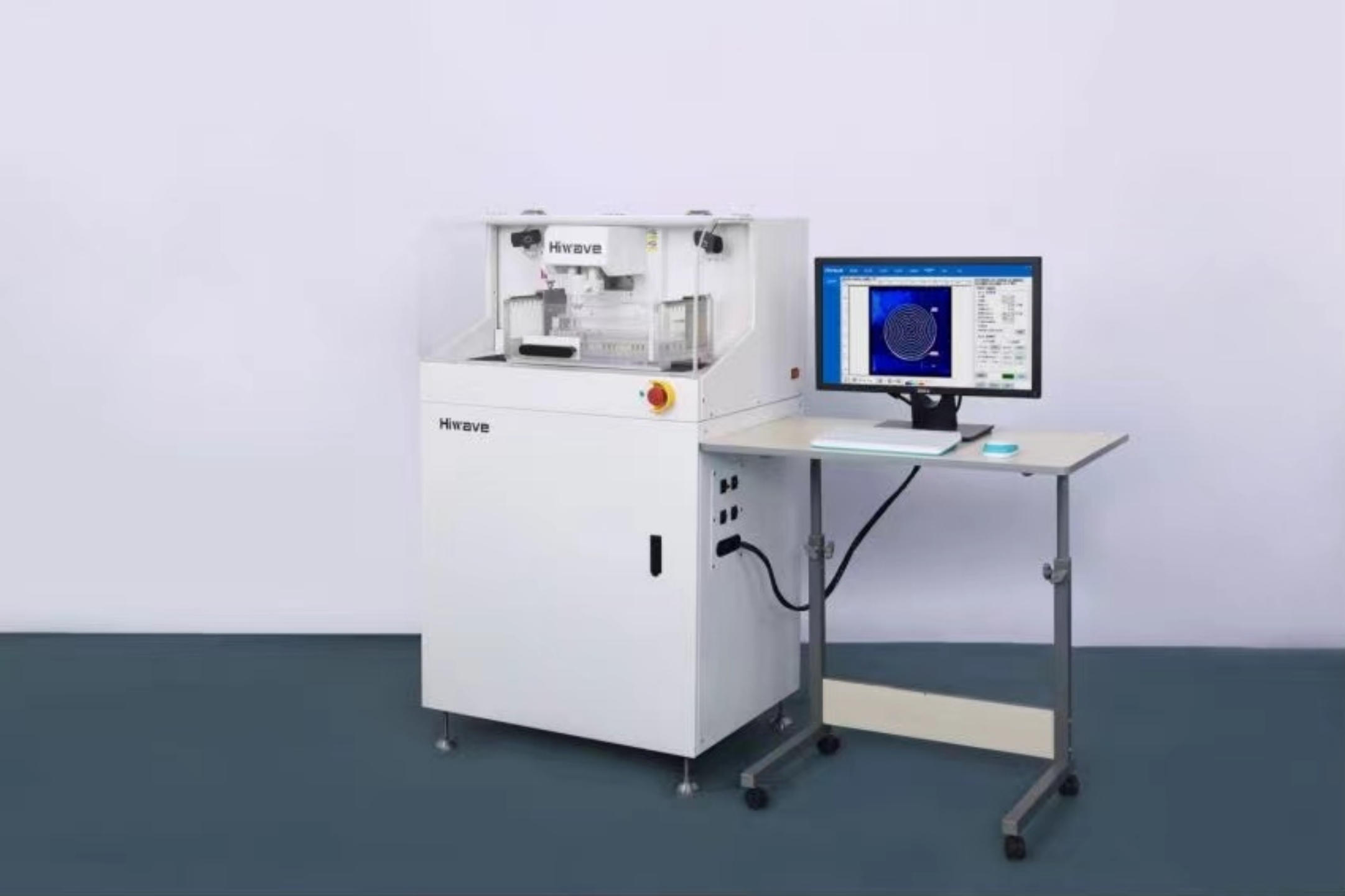

水浸超声扫描显微镜是一款集多种扫描模式于一身的高精无损检测成像设备。检测精度高,分辨缺陷能力强,检测结果精准,检测范围广泛,对人体没有危害。

其中,上海Hiwave和伍智造营自主研发的水浸超声扫描显微镜搭载超声超声反射、透射成像法以及超声A扫描、超声B扫描、超声C扫描、超声T扫描不同检测方法与模式。以稳定的产品性能、微米级的高精分辨力、丰富的扫描模式在半导体内部缺陷检测领域中取得了不错的口碑。且受到了华为、中国电子科技、等众多龙头企业的赞赏!

![[x]](static/picture/closeimgfz1.svg)